Single to 2-3 Storey LGS Structures

It is generally recognised Internationally that the C89mm profile Framer manufacturing to a maximum gauge of 1.2mm is the most popular for a

wide range of applications for single to 3 level residential houses and for

light commercial structures

The SFS-SP120 C89 profile Framer (0.6mm - 1.2mm) for Load Bearing Structures

from single to 3 levels for medium spans. For wider spans, heavier

design loads and thicker perimeter structural walls for greater thermal properties

combine with a SFS-SP120 C140 profile Framer (0.6mm - 1.2mm)

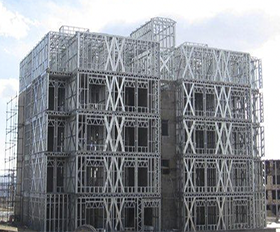

Multi-level Structures

For larger span structures and multi-storey over 3 levels typically up

to 5 to 6 levels requires a heavier 1.6mm gauge and wider profile

The SFS-SP160 C89 profile Framer (0.75mm - 1.6mm gauge) for Load Bearing

Structures up to 6 levels as illustrated.

For wider spans, heavier bearing loads and wider profile perimeter structural walls for

increased line loads that also provide greater thermal properties extend your LGS manufacturing with a SFS-SP160 C140 profile Framer (0.75mm - 1.6mm gauge)

Multi-Storey Building Facades

Hi-Rise Apartment Complex

This Luxury Apartment Development is conventional concrete construction.

To fast track the completion to the market the perimeter wall frames were constructed from 140mm 1.2mm gauge galvanised steel profiles.

The external cladding facade systems as illustrated are mounted to the LGS 140mm Galvanised Steel Frames

The SFS-SP120 C140 profile Framer (0.75mm - 1.2mm gauge) manufactures this frame profile for Rain Screen Facade Systems ready for on-site assembly & installation

Office Building - Terracotta Tiled Facade

A commercial building in the UK with an external facade of terracotta tiles mounted to a rain screen system. Supporting the external rain screen facade are LGS Frames using 1.2mm gauge galvanised steel profiles, assembled & installed onsite, a proven fast track build solution eliminating wet trade works

The SFS-SP120 C89 profile Framer (0.6mm - 1.2mm gauge) manufacturers this LGS Profile for the Facade Steel Frames ready for fast cost effective on-site assembly & installation

The Rain Screen Facade support rails are fixed directly to the LGS Frames

Roof Trusses & Roof Panels

Retail & Warehouse Building

Retail Outlet & Warehouse unsupported wide span Roof Trusses and Roof Panels manufactured from C140 profiles (1.2mm gauge) with medium tensile galvanised steel coils.

The Roof Trusses with C140 profile Roof Panels were lifted into place

and the whole operation completed in 3 days with 4 men and a HIAB Truck

The SFS-SP120 C140 profile Framer (0.75mm - 1.2mm) manufactured the frame profiles

for fast cost effective factory frame assembly, delivered ready for site installation

Residential Truss & Panel Roofs

The majority of residential roof trusses & panels are manufactured with a

SP120 Framer (89mm profile) up to 1.2mm gauge for most medium span applications, when higher design loads & wider unsupported spans are required a SP160 Framer (89mm profile) up to 1.6mm gauge is widely used.

The SFS-SP120 C89 profile Framer (0.6mm - 1.2mm gauge) up to medium span roof trusses, beams & floor joists or a SFS-SP160 C89 profile Framer (0.75mm - 1.6mm gauge) for medium to wide unsupported spans

Floor Joists

Lattice Beam Floor Joists

The open web of a lattice beam joist enables clear and easy access for all MEP Services, conduits, cabling, plumbing pipes, ventilation flexible ducting and a ceiling cavity void for recessed lighting fittings with the added benefit of space for acoustic and thermal insulation blankets eg; "Rockwool" material.

The SFS-SP120 C89 Framer (0.6mm - 1.2mm gauge) up to medium span floor joists

and beams or for medium to wide span floor joists requires a SFS-SP160 Framer 89mm profile thickness ranging from (0.6mm - 1.6mm gauge)

Robust CFB or Concrete Screed Floors

Composite flooring board such as CFB (cement fibre board) for sole occupancy multi-level housing or a high performance acoustic and fire rated conventional or light weight concrete floor finish screed using a trapezoidal metal decking as the formwork without back propping for fast track construction solution

The SFS-MP150 multi-profile Framer is a very cost effective solution with the ability to manufacture 3 Profile widths 75mm|89mm|140mm (0.75mm - 1.6mm) for a wide range

of LGS Structures and medium to wide span Floor Joists and Beams

Bathroom Pods

LGS Frame Pods

The C75 (75mm) profile width that is becoming accepted as the International standard for LGS bathroom pod cages with C65 (65mm) also used in the Bathroom Pod Industry.

LGS Pod Frames are now specified for the majority of Bathroom Pod contracts due to proven robust performance and light weight construction benefits.

Ability for a POD Manufacturer to react instantly to design changes with an automated Pod LGS manufacturing process with zero error for total accuracy.

LGS Production Benefits

The Bathroom POD Company can design a LGS Pod Cage and manufacture the prototype Bathroom Pod Cage, make changes in less than a day, not weeks.

Manufacture precise repetitive LGS POD Cage Frames to within (+- 1mm) with no manual

cutting, welding or specialist trade skills

All of the POD Cage Frame profile connections & service holes are pre-punched for rapid assembly and simplified installation of MEP Plumbing, Electrical cables and conduits.

The SFS-SP120 C65 profile or C75 profile Framers are available for the POD Cage profiles with high speed production up to 620linear/metres/Hr

Dry Wall Framing

Commercial Dry Wall Framing

The LGS Manufacturer can utilize their C89mm profile Framer to produce Dry Wall Frames, with all dimensions from architectural Auto-CAD drawings to design and manufacture all the profile components for complete LGS frames

Packaged into bundles to be delivered to site with the CADesign Software production A4 drawings detailing the assembly order & dimensions. To locate where the frames are to be installed the frames are identified with an inkjet ID during manufacture.

Less than 2% Material Wastage

As Dry Wall Track & Stud lengths are cut on-site the material wastage is very high, acknowledged to be in excess of 25% contributing to waste removal logistics & cost. Material waste with LGS technology is typically less than 2%

The heavier gauge of the 0.6mm LGS Frames results in very robust walls with MEP services installed before the gypsum board is fitted thereby reducing damage

The SFS-SP120 and SP160 Framers manufacture true un-swaged cut to length studs

and U Channel Top/Bottom Plates specially for Dry Wall high speed production at over 650linear/metres/Hr