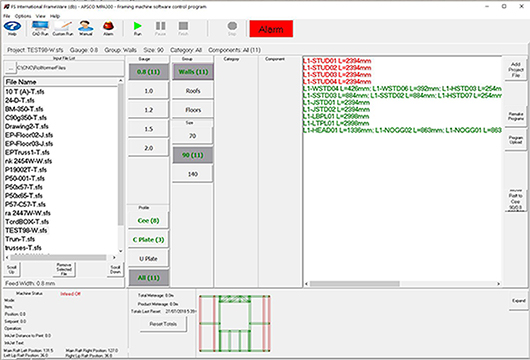

Real Time Information displayed on the Operators Monitor

-

Calibrate and Optimise your Framer to maintain absolute precision

-

Machine Status

Automatic | Manual | Pause | Alarm -

Alert Notifications

Lubricant Level Low | Change Oil Filter | Shield Guards Opened

No Steel Alert -

Framer Status

Motor Speed in mm/second | Oil Pressure in Kg/cm2

Machine Log

Drive Motor | Hydraulic Pump | Inkjet Printer Enabled/Disabled -

Production Status

Details of Panel operations | Profile Lengths | Production queue

Preview of Frame profiles not yet manufactured | Profile in production | Frame Profiles completed -

Flexible Production Options

Frames can even be added to the Production queue while in Production Mode -

Sequence of Frame Production Status

The order of the Frames for production can be changed by the Operator

From Vertex BD CADesign File to Frame Production File

Vertex BD Software converts your LGS CADesign Project into a Production File to run on your Framer

Six Simple Steps from CADesign to Production

- Design and Analysis your LGS Project with Vertex BD Software

- Vertex BD converts your LGS 3D Model into a Production File

- Load your LGS Production File onto a USB Stick

- Load the USB Stick into the Framer via the Monitor Interface

- Select the Frames to manufacture or the whole LGS Project

- Commence manufacturing all of the LGS Frame profiles

FrameWare Machine Control is our easy to use

touch screen graphic interface for the Operator

-

The Operator can select just individual frames or the whole LGS Project

-

Production of all the frames is fully automatic

-

As each LGS Frame is manufactured the screen displays the frame and

the actual production operations -

Graphic view of the frame components been made in real time

-

The production process of each frame profile is displayed of the operations

individual lengths and frame dimensions -

The Steel Coil usage is estimated to track coil yield

-

The Operator can add, modify or cancel a task while in single batch mode

or in full production mode -

A important zero material waste management feature is the ability to

Auto Save a project production run before the system is closed down and then

continue the production file from the previous day

Graphic Display of the Framer management & the

automated frame manufacturing process

Total Management of the Framer and Production Control via the touch screen

including machine maintenance analysis and diagnostics

ProCam Production Optimisation

Software

Converts the data from

Design & Detailing CAD Software

ProCAM converts your Vertex | StrucSoft | ProCAM CADesign

LGS Projects into production ready files

- Split & Create Production files to multiple Framers in one or more locations

- Manage by Reporting on exact production times for each frame for each Framer

- Graphic Real Time Touch Screen Interface of all Framer Operations

- Monitors & displays production errors and warnings for the Framer Operator

- Framer Management touch screen control & real time system analysis

- Displays the frame production with colour codes for all stages of manufacture