The SFS Multi-Profile Framer Solution

Our SFS MP150 Framer - manufactures 3 profile widths

SFS MP150 Multi-Profile Framer

MULTIPLE PROFILES FOR ALL FRAMES, TRUSSES, BEAMS, FLOOR JOISTS (0.75 - 1.6mm) (Imperial 22 - 16gauge)

Standard Profile Widths 75mm | 89mm | 140mm

Tool Stations available for additional profile widths

The SFS MP150 Multi-Profile Framer has all of the manufacturing operations & features of our proven and reliable SP160 Series Framer with the capability to produce three profiles for all your frames, trusses and floor joists enabling the LGS Manufacturer to deliver a wide range of construction projects.

The frame profiles are produced from steel coil material ranging from 0.7mm to 1.6mm thickness (22 - 16gauge) ideally suited for both residential and commercial applications

Construction Applications

SIX STOREY APARTMENT BUILDINGS | LARGE MULTI-LEVEL RESIDENTIAL HOUSES

20 METRE SPAN WAREHOUSES | STORAGE FACILITIES | OFFICE BUILDINGS | WAREHOUSE EXTERNAL WALL IN-FILL FRAMING | HIGH RISE OFFICE BUILDING RAIN SCREEN SYSTEM SUPPORT WALLS | MODULAR BUILD | BATHROOM PODS | FLOOR JOISTS | BEAMS | ROOF TRUSSES

With the automatic option all the rollers in the rolling bay are servo adjusted to a new profile at the touch of a button and our Operator completes the changeover from one profile to another in less than it takes to change the steel coil, a matter of minutes, this is a very easy machine to operate and maintain, fast & very reliable

FULL TECHNICAL SPECIFICATION

Auto Gauge

Rolling Bay

The entire rolling bay sets of rollers are auto-gauging, when you change the steel thickness the rollers self-adjust to the new gauge, no manual re-setting of every roller by the Operator

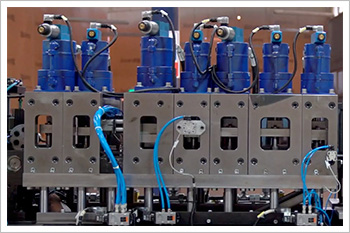

Tool Stations

Easy Access

Individual tool stations to simplify die/tool changes with all hydraulic lines, connections, solenoid valves visible to the Operator for ease of servicing to ensure rapid low cost maintenance

Sensors

Auto Monitoring

Sensors regulate the Framer performance to maximise the production rate and also record all operations providing shearing and punching data for maintenance reporting to the Operator

Quick Change

30 minutes

With a simple manual or automatic option changeover our customers can now afford a multi-profile machine that does not require skilled technicians to operate with very low maintenance cost

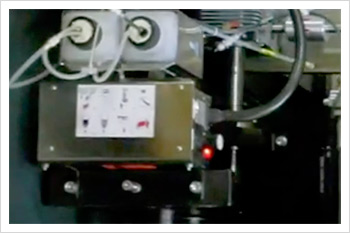

Profile Marking

ID & Branding

The Framer is fitted with a Mathews Inkjet System & single printhead for profile ID/numbering. An additional printhead is optional for dual printing to both sides of the profile flanges