SP160 140mm Profile Framer

High speed manufacturing of a single profile ranging in thickness from 0.75mm to 1.2mm

A 140mm Profile Framer for Multi-Storey Apartment Buildings

Large Residential Houses, Commercial Units, Transportable Office

and Amenities Modular Construction

Applications

SIX STOREY APARTMENT BUILDINGS | LARGE MULTI-LEVEL RESIDENTIAL HOUSES

20 METRE SPAN WAREHOUSES | STORAGE FACILITIES | OFFICE BUILDINGS | WAREHOUSE EXTERNAL WALL IN-FILL FRAMING | HIGH RISE OFFICE BUILDING RAIN SCREEN SYSTEM SUPPORT WALLS | FLOOR JOISTS | BEAMS | ROOF TRUSSES

| Technical Specification | |

|---|---|

| Model | SFS-International SP160 Series Framer |

| Function | Framing & Truss Structures |

| Typical Production Speed | 280-750 Metres/Hr Design Dependent |

| Line Speed | 2,700 Metres/Hr (not production speed) |

| Machine Operating System | FrameWare Software |

| CADesign Software | Vertex BD Software | StrucSoft MWF Solutions |

| Industrial Touch Screen | 17inch Screen PC Windows Operating System |

| Data Input | USB Plug - USB Stick |

| Multi-Task Operations | Add | Modify | Cancel Production |

| Production Graphics | All Operations shown in real time |

| Production Options | Batch or Single Profile Production |

| Data Storage | System Save Off Auto Save - Zero Waste |

| Ambient Air Temperature | Operating Range 0-35Deg C |

| Machine Data | |

|---|---|

| Machine Chassis | CNC Machined Box Structure |

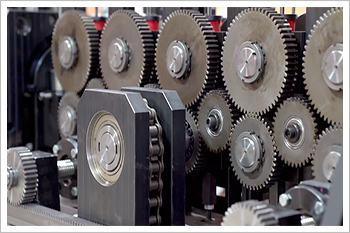

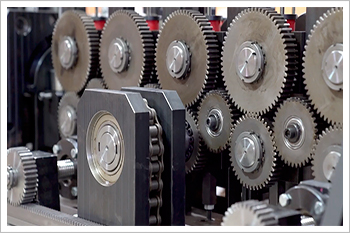

| Power Transmission | Geared |

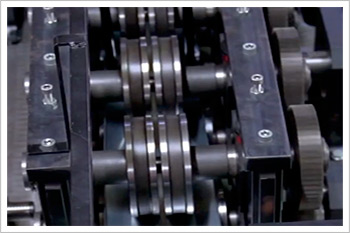

| Roll Forming Stations | 11 Roller Profile Forming Sets |

| AC Geared Motor | Drive Power Capacity 15kW |

| VFD Synchronised | State of the Art Control System |

| Hydraulic Pump Motor | Motor Capacity 11kW (15HP) |

| Framer Power Supply | 36kW | 45A | MCCB 60A |

| Mains Electrical Supply | 3phase, 415v | 50-60Hz | N+E |

| Hydraulic Tank Capacity | 100 Litres |

| Hydraulic Cooling System | Radiator with Auto Operation Fan |

| Inkjet Profile Printer | Mathews Mperia Lite OEM |

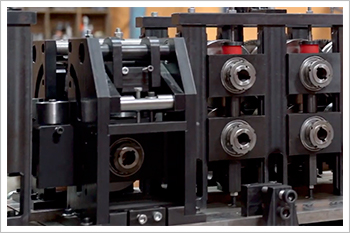

| Gauge Adjustment | Auto Adjustors on Roller Sets |

| Self Lubricating | Steel Coil Lubricating System |

| Physical Data | |

|---|---|

| Length | 5100mm |

| Height | 1650mm |

| Width | 1200mm |

| Machine Weight | 4,600Kg (approximately) |

| Production Footprint | 13.8Metre length x 1.2Metre |

Reliable Technology Built to Last

“Precision Accuracy with Zero Tolerance and High Volume Production ”

-

- Fast, reliable and very accurate steel frame manufacturing solution by SFS International resulting in very cost effective design & build technology

- SFS International have a reputation for manufacturing well engineered, industrial grade Framers to International standards built with ease of maintenance in mind

- SFS International Framers are designed and built with high quality International

electronic components and electrical systems

| Framer Features | |

|---|---|

|

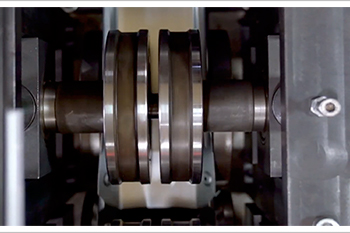

Eleven (11) roller sets in the rolling bay to precisely cold roll the steel coil strip into the C Channel Profile into a shape with well defined radius's to the web, flanges and lips. |

|

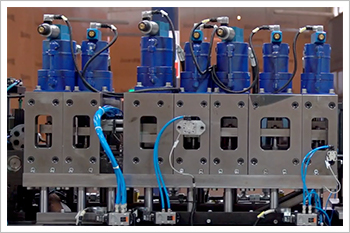

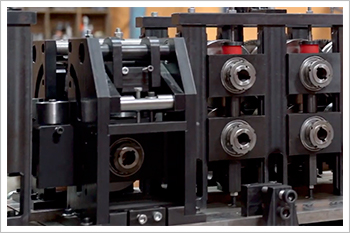

Rail mounted hydraulic lines made accessible for visual routine check & ease of maintenance of all tool station operations, the Operator requires no specialist skills to identify and service when required |

|

Sensors regulate the Framer Performance so the operations of all Tool Stations are optimised for maximum production and the condition of working components are constantly monitored. |

|

Auto Gauging of the Rollers to adapt to the steel gauge loaded into the Framer without the Framer Operator having to manually adjust all the roller settings individually after loading a different gauge steel |

|

Geared Rolling Bay all profiling rollers are driven by precision machined hardened gears to ensure long life performance & accurate positioning in excess of half a million metres with minimal service & maintenance |

|

Individual Hydraulic Cylinders & Tool Stations cylinder mounted actuating solenoids & valves, accessible hydraulic lines, and individual tool stations for simplified maintenance and servicing by your Framer Operator |

|

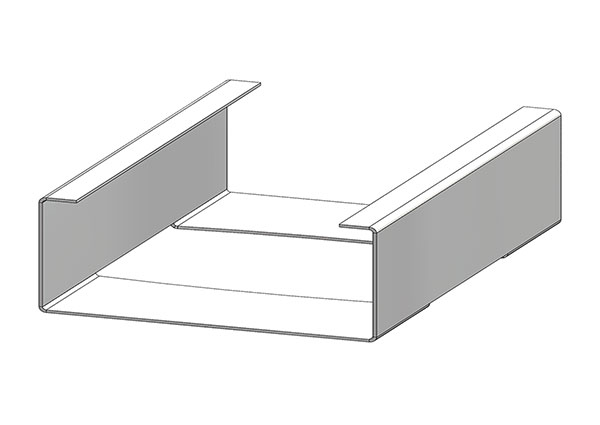

Automatic Track Manufacture at high speed producing U Channel profiles for True Track & Stud production, Truss & Beam profiles, with wider flanges eliminating the swage operation for ease of frame assembly |

| Motorised De-Coiler | |

|---|---|

| Automatic Feed | Motorised Power Drive |

| Pressure Arm | Pneumatically controlled to restrain the steel coil |

| Maximum Width Coil | 250mm Coil Strip Width |

| Coil Inner Diameter Hub | 460 - 520mm Dia |

| Maximum Outer Coil | 1200mm Dia |

| Maximum Loading | 3,000Kg |

| Hub Arms | Manual Expansion |

| Hydraulic Expansion Option Available | |

| Motor Power | 2.2kW |

| Power Supply | Three phase | 50-60Hz supply via the Framer |

| De-Coiler Physical Data | |

|---|---|

| Length | 750mm De-Coiler Body 1200mm with Steel Coil |

| Height | 750mm Body 1950mm inc Pressure Arm |

| Width | 1000mm |

| De-Coiler Weight | 700Kg (approximately) |

De-Coiler Key Features

“Steel Coil up to 3 Ton Capacity with Auto-Feed Operation”

-

-

- A Optional Hydraulically operated Hub is available for expanding and contracting the Hub to clamp the Steel Coil when loading and removing a Steel Coil instead of this being a manual operation

- Automatic Variable Speed Control of the steel coil feed into the Framer

- Pneumatic pressure arm to restrain the steel coil end from un-raveling to prevent potential injury when loading/un-loading

- Mains supply & control cable to the De-Coiler via a plug/socket at the Framer, a separate electrical supply

is not required - When positioning the De-Coiler the hub can be either left or right sided (shown with the hub on the right side) for loading of the coil

“Pressure arm for Health & Safety of the Operator ”

-

| Profile Specification | |

|---|---|

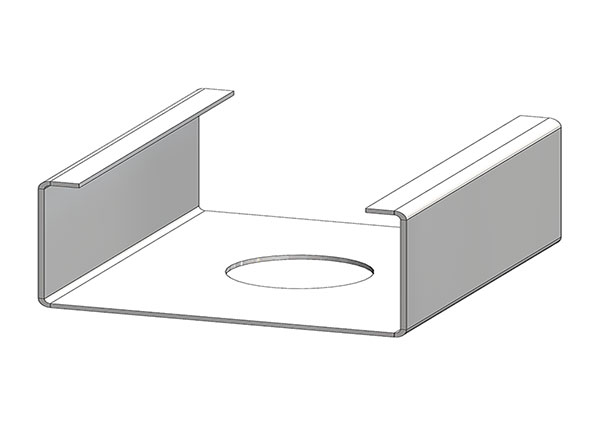

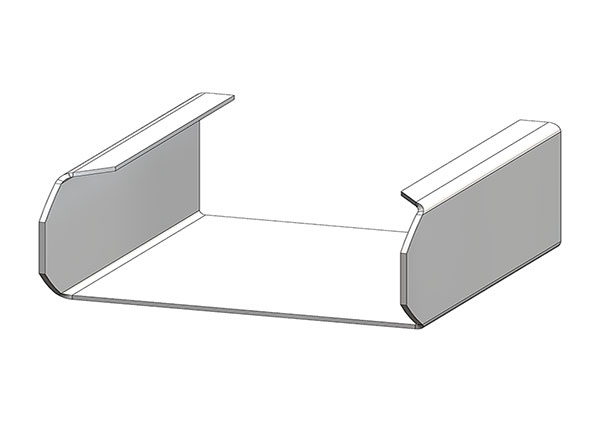

| Profile Type | C Channel |

| Profile Width | 140mm Metric | 5.5" Imperial |

| Track Width | 143mm Metric | 5.5" Imperial |

| Profile Dimensions | 140mm Web | 41mm Flange | 10mm Lip |

| Material | Zinc Galvanised Coated Steel Strip |

| Material Thickness | 0.7mm to 1.2mm (22g - 16g) |

| Galvanised Coating | Grade Range Z170 - Z270 |

| Nominal Coil Strip Width | 234mm |

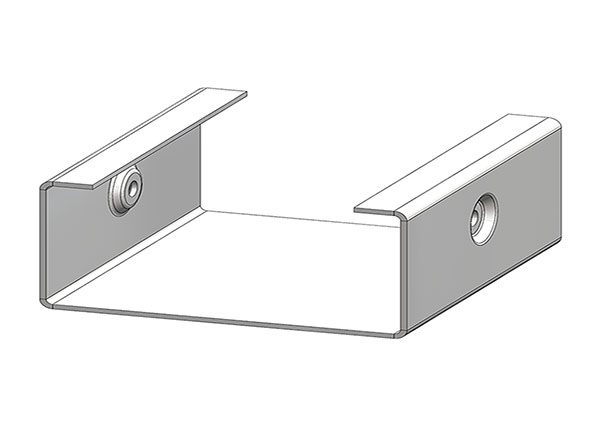

| Profile Connections | |

|---|---|

| Dimpled Flange Connection | 3.5mm Punched Hole |

| Service Hole | 33mm Dia ( can be customised) |

| Bolt & Anchor Bolt Hole | 13mm Dia (can be customised) |

| End Truss Notch | 45Deg Chamfer Truss Cut |

| Web Index Holes (2) | Frame to Frame Screw Connections |

| Profile Operations | ||

|---|---|---|

| Tool Station | Automated Hydraulics | |

| Operations (9) | Description of Profile Operations | |

| 1 | Track & Stud | Automated Track Width change for effortless Stud Insert |

| 2 | 13mm Dia Bolt Hole | For Bottom Plate Anchor Bolts or bolting Frames together |

| 3 | 3.5mm Dia Web Holes (2) | Index Holes for locating Frame to Frame Fixing Screws |

| 4 | 33mm Dia Service Hole | Hole through Frame Profile Web for Services |

| 5 | End Chamfer | 45Deg Chamfer at the end of Truss or Beam Web Members |

| 6 | Dimple Connection Holes | Dimpled 3.5mm Dia connection holes for flush Fixings |

| 7 | Web Notch | For Single & Continuous Nogs |

| 8 | Lip Notch | Lip cut to permit inserting a Profile into another Profile |

| 9 | Shear | Part Cut or Full Cut Guillotine Shear |

Framer Profile Operations

SP160 C140mm Framer Package